|

|

|

|

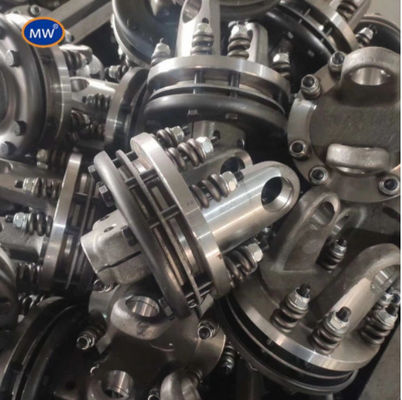

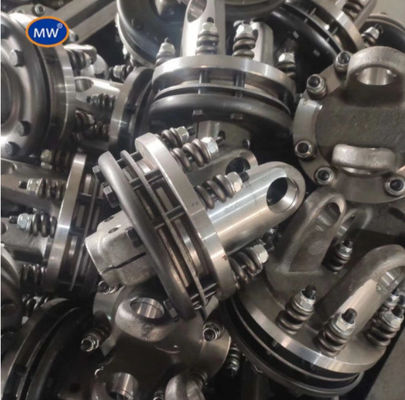

Splined End Diameter 60 Mm PTO Drive Shafts Designed for Heavy Duty Maximum Speed 1000 Rpm and Splined End Size 20 Teeth

| Velocità massima: | 1000 giri al minuto | Peso: | 10KG |

|---|---|---|---|

| Diametro della flangia: | 100 mm | Materiale: | Acciaio |

| Diametro dell'estremità della spina: | 60 mm | Lunghezza: | 1,5 metri |

| Lunghezza della spina: | 50 mm | Certificazioni: | ISO 9001 |

Product Description:

The PTO Drive Shafts are precision-engineered components designed to deliver reliable power transmission in a variety of agricultural and industrial machinery. Crafted from high-quality steel, these drive shafts are built to withstand demanding operational conditions, ensuring durability and long-lasting performance. With a keyway size of 10 mm, the PTO Drive Shafts provide a secure and precise fit, enabling efficient torque transfer and minimizing the risk of slippage during use.

One of the standout features of these PTO Drive Shafts is their robust construction, which includes a flange thickness of 20 mm. This substantial flange thickness enhances the structural integrity of the shaft, allowing it to handle high levels of stress and torque without deformation. The shaft’s total weight of 10 kg reflects its solid build, balancing strength with manageable mass for ease of installation and maintenance.

The PTO Drive Shafts utilize a PTO shaft tube as their power source, making them compatible with a wide range of power take-off systems commonly found in tractors and other machinery. This compatibility ensures seamless integration and reliable power delivery, which is crucial for efficient operation of equipment such as mowers, balers, and other PTO-driven implements.

Incorporating a forged shaft design, these drive shafts benefit from the superior mechanical properties that forging imparts. Forged shafts exhibit enhanced strength, toughness, and resistance to fatigue compared to cast or machined alternatives. This makes them ideal for applications where consistent performance and longevity are paramount. The forging process also ensures uniform grain structure, reducing the likelihood of cracks and failures under high stress.

The PTO Drive Shafts also feature components such as the CV axle shaft and drive shaft pin, which contribute to their overall functionality and reliability. The CV axle shaft allows for smooth and flexible transmission of power even when the shaft is at an angle, accommodating the movements and vibrations commonly experienced in agricultural machinery. Meanwhile, the drive shaft pin plays a critical role in securing the connection between the shaft and other drivetrain components, maintaining alignment and preventing disengagement during operation.

These drive shafts are engineered to meet the stringent demands of modern agricultural equipment, providing operators with confidence in the performance and safety of their machinery. The combination of a 10 mm keyway size, durable steel material, and a thick 20 mm flange ensures that the PTO Drive Shafts can handle significant torque loads while maintaining structural stability. This makes them suitable for a broad spectrum of applications, from light-duty tasks to heavy-duty agricultural work.

Maintenance and replacement of PTO Drive Shafts are simplified by their standardized dimensions and robust design. The 10 mm keyway size allows for compatibility with a variety of couplings and fittings, facilitating quick and secure installation. Additionally, the use of a forged shaft enhances the shaft’s resistance to wear and tear, reducing downtime and the need for frequent replacements.

In summary, the PTO Drive Shafts combine strength, reliability, and precision engineering to deliver exceptional performance in power transmission applications. Their forged shaft construction, integration of CV axle shafts, and secure drive shaft pins ensure that they can withstand the rigors of agricultural and industrial use. With a steel build, 20 mm flange thickness, and a manageable weight of 10 kg, these drive shafts provide an optimal balance of durability and ease of handling. Whether used in tractors or other PTO-driven machinery, they offer a dependable solution for efficient and effective power transfer.

Features:

- Product Name: PTO Drive Shafts

- Splined End Length: 50 Mm

- Shaft Diameter: 50 Mm

- Keyway Size: 10 Mm

- Flange Diameter: 100 Mm

- Certified with ISO 9001 for quality assurance

- High-quality Forging Shaft for enhanced strength and durability

- Compatible with Drive Shaft Center Bearing for smooth operation

- Designed for optimal performance with Gears and Shafts systems

Technical Parameters:

| Safety Features | Overload Protection |

| Weight | 10 Kg |

| Flange Thickness | 20 Mm |

| Maximum Speed | 1000 Rpm |

| Splined End Size | 20 Teeth |

| Certifications | ISO 9001 |

| Material | Steel |

| Maximum Torque | 500 Nm |

| Flange Diameter | 100 Mm |

| Power Source | Pto Shaft Tube |

Applications:

The MW PTO Drive Shafts, originating from China, are engineered to deliver exceptional performance and durability in various agricultural and industrial applications. Weighing 10 Kg and crafted from high-quality steel, these drive shafts feature a shaft diameter of 50 mm and a keyway size of 10 mm, ensuring strong and reliable power transmission. Designed specifically to operate with a PTO shaft tube as the power source, MW PTO Drive Shafts are ideal for connecting and transferring power from tractor engines to attached implements and machinery.

These drive shafts are commonly used in scenarios requiring robust torque transfer, such as in farming equipment including mowers, balers, tillers, and harvesters. The steel construction and precise forging shafts manufacturing process provide enhanced strength and resistance to wear and tear, making them suitable for heavy-duty use in demanding environments. The inclusion of hollow shaft motor compatibility further expands their application range, allowing seamless integration with various motorized systems that utilize hollow shafts for efficient power delivery.

In agricultural operations, MW PTO Drive Shafts enable farmers to efficiently operate equipment by transmitting rotational power from the tractor’s PTO to implements. This is essential during planting, harvesting, and soil preparation seasons when reliable machinery performance is critical. Similarly, in industrial settings, these drive shafts support the operation of conveyor belts, mixers, and other machinery driven by hollow shaft motors, ensuring smooth and continuous power flow.

Additionally, the PTO Drive Shafts by MW are suitable for use in maintenance and repair scenarios where replacement of worn or damaged shafts is necessary to restore equipment functionality. Their standardized dimensions, including a 50 mm shaft diameter and 10 mm keyway size, allow for easy installation and compatibility with a wide range of machines and hollow shaft motor applications.

Overall, the MW PTO Drive Shafts stand out as a reliable and durable solution for power transmission needs in agricultural and industrial environments. Their strong steel build, precise forging shafts design, and compatibility with hollow shaft motors make them indispensable components for ensuring efficient and uninterrupted operation of PTO-driven equipment.

Customization:

Our MW PTO Drive Shafts are expertly crafted in CHINA using high-quality steel to ensure durability and performance. Although there is no specific model number, these drive shafts feature a keyway size of 10 mm and a splined end diameter of 60 mm, making them compatible with various excavator components. Certified with ISO 9001, our PTO Drive Shafts guarantee reliable quality and meet international standards. Designed to handle a maximum torque of 500 Nm, they are ideal for heavy-duty applications. We also offer customization services to tailor the PTO Drive Shafts to your specific requirements, including compatibility with Excavator Shaft assemblies and Excavator Drive Sprockets. Whether you need to fit Excavator Drive Sprockets or other related parts, our team can provide precise modifications to ensure optimal performance and longevity.

Support and Services:

Our PTO Drive Shafts are designed for reliable performance and long-lasting durability in agricultural and industrial applications. For technical support, please ensure you have the model number and specifications of your PTO drive shaft ready when seeking assistance. Our support team can provide guidance on installation, maintenance, troubleshooting, and replacement parts to keep your equipment running smoothly. We recommend regular inspection of the drive shaft for wear, proper lubrication, and alignment to prevent operational issues. For service and repair, use only genuine replacement parts to maintain the integrity and safety of your PTO drive shaft system.

Packing and Shipping:

Our PTO Drive Shafts are carefully packaged to ensure maximum protection during transit. Each shaft is wrapped in protective materials to prevent damage from moisture, dust, and impact. The packaging is designed to keep the product secure and intact, minimizing the risk of any dents or scratches.

We offer reliable shipping options with trusted carriers to deliver your PTO Drive Shafts promptly and safely. Tracking information is provided with every order, allowing you to monitor the shipment status from dispatch to delivery. For bulk orders, we use sturdy crates or pallets to facilitate safe handling and transportation.

Whether you are ordering a single PTO Drive Shaft or multiple units, we prioritize secure packaging and efficient shipping to ensure your product arrives in perfect condition and on time.

FAQ:

Q1: What brand manufactures the PTO Drive Shafts?

A1: The PTO Drive Shafts are manufactured by the brand MW.

Q2: Do the PTO Drive Shafts have a specific model number?

A2: No, the PTO Drive Shafts do not have a specific model number.

Q3: Where are the PTO Drive Shafts produced?

A3: The PTO Drive Shafts are made in China.

Q4: What applications are the MW PTO Drive Shafts suitable for?

A4: MW PTO Drive Shafts are suitable for various agricultural machinery and equipment requiring power transmission.

Q5: What materials are used in the construction of MW PTO Drive Shafts?

A5: MW PTO Drive Shafts are made from high-quality steel to ensure durability and reliable performance.

Asse di PTO,

asse di pto del trattore

Persona di contatto: Mrs. Lily Mao

Telefono: 008613588811830

Fax: 86-571-88844378

-

Alberi motore di PTO del trasporto di energia per l'attrezzo rotatorio, asse della presa di potenza

-

Sostituzione degli alberi motore del PTO del trattore agricolo/alberi motore su ordine

-

Alberi motore del PTO del cardano dell'azienda agricola di Professiona con la frizione di Overruning

-

Gli alberi motore su ordinazione del PTO della macchina della piantatrice Ratchet l'albero motore del limitatore di coppia

-

Albero motore flessibile PTO dei ricambi auto/asse di cardano per agricoltura Rotavator

-

limitatore di coppia del perno di sicurezza degli alberi motore del PTO della presa di potenza 4x4